Company Profile

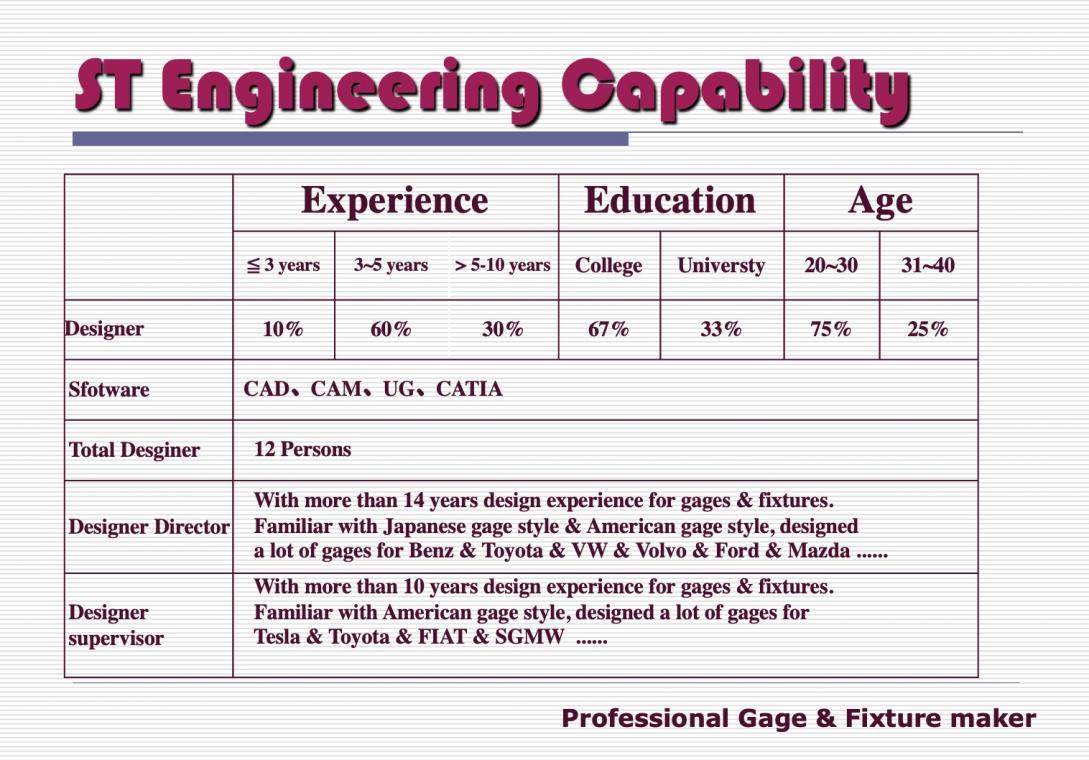

Shing tin establish on year 2017, with 10+ experience gage designer providing the best design gage/fixture with all around the car including the exterior, interior, metal/plastic part gage, CMM fixture and assembly fixture etc.

Meantime, We have more than 15 years experience on exporting the inspection gage or fixture to north America, Euro and Mexico etc. Our main customers include Tesla US, Toyota and Mercedes Benz etc.

Shing tin has 5000m2 manufacturing plant which is located in jiang su with 5 high precision CMM with over 5M x 2.5M and 8 high precision CNC machine including the 5 axis CNC machine (over 3M x 2M x 1.2M)